Table of Contents

Report

Metallic & Fabric Dome

Authors:

- Arne Speckstadt

- Klaudia Skonieczna

- Gergely Rajnai

- Jairo Pérez Daza

- Bogdan Marius Barb

Acknowledgement

First of all, we would like to thank ISEP for giving us an opportunity of being a part of European Project Semester, broaden our horizons, getting knowledge on different fields of study with people from all over the world.

What is more we would like to thank all of our supervisors - Abel Duarte, Fernando Ferreira, Benedita Malheiro, Cristina Ribeiro, Manuel Silva, Paulo Ferreira, Pedro Guedes for helping us solve problems and doubts but also for showing patience during the process of developing our project.

Last but not least, we want to give credit to our teachers, who tried to pass the knowledge without which we wouldn't be able to finish the project, but also for their advices regarding our Erasmus journey.

Glossary

<WRAP box 400px>

| Abbreviation | Description |

|---|---|

| EPS | European Project Semester |

| ISEP | Instituto Superior de Engenharia do Porto |

| USB | Universal Serial Bus |

| WBS | Work Breakdown Structure |

| RACI | Responsible, Accountable, Consulted, Informed |

| PESTLE | Political, Economical, Social, Technological, Legal, Environmental |

| SWOT | Strengths, Weaknesses, Opportunities, Threats |

| SMART | Specific, Measurable, Achievable, Realistic, Timed |

| φ | Golden ratio |

| s | length of the edges of an icosahedron |

| r | radius |

| € | euro |

| EU | European Union |

| EC | European Commission |

| U | Voltage |

| V | Volt |

| I | Current |

| mA | milliampere |

| P | Power |

| W | Watt |

| °C | Degree Celsius |

| Pcs | Pieces |

</WRAP>

1. Introduction

1.1 Presentation

Our team consists of 5 students from different countries and with different scientific background who came to Portugal - to spend one semester at Instituto Superior de Engenharia do Porto at European Project Semester. We are: Arne Speckstadt from Belgium, studying Construction; Klaudia Skonieczna from Poland, studying Information Systems in Logistics; Gergely Rajnai from Hungary, studying Electrical Engineering; Jairo Pérez Daza from Spain, studying Mechanical Engineering and Barb Bogdan Marius from Romania, studying Mechatronics.

1.2 Motivation

Why to go on Erasmus?

We all wanted something more from our studies. We also wanted to get to know other people and cultures.

And why Metallic & Fabric Dome?

After receiving the list of possible topics we wanted to choose the one that could combine our different scientific background and also the one that we would be interested in using. That is why our first choice was Metallic&Fabric Dome. As we live in a consumer society and we are part of it, we found making a leisure time place-such as a winter garden, the most appealing to us.

1.3 Problem

Our task is to design and build a Metallic & Fabric Dome, that must be a V3 or V4 geo-dome with a diameter of 6.8 metres, which will be used as a winter garden. Our main obstacle is the implementation of automatic windows and doors, as our budget for building the scale model is very limited, so finding both - materials for the dome and electrical components is a hard task. What is more using the shape of triangle or hexagon for windows and door is not usually common, so implementing that kind of solution requires much more work and is definitely more challenging then in case of regular shape like rectangle. Last but not least, the dome should be resistant while in the same time it should be portable and easy to build for the client, so combining this two establishments can be problematic.

1.4 Objectives

The goal is to design and build a Metallic & Fabric Dome that will be used as a winter garden. Our dome should be durable, in the same time portable, so it could be moved easily, while staying as sustainable as possible. Our product will be used as leisure time place so the design should be appealing to a potential client. What is also an important aspect of the dome is monitoring the temperature and humidity inside, so the sensors should transmit information about it and if there is the need the windows will open or close.

1.5 Requirements

Our main requirements are:

- Reuse provided materials

- Use low cost hardware solutions

- Use opensource software

- Adopt the International System of Units

What is more we have to think about other requirements from the perspective of an author but also a client, like:

- Low cost materials

- Sustainability of our product

- Design

- Functionality (monitoring a humidity and temperature inside the dome)

1.6 Functional Tests

The temperature uniformity inside the dome provides us a real measure. That’s why our main functional test will be to include temperature and humidity sensors. They will be able to catch the information. Depending on the temperature, Arduino must be able to manage and to order to the servo-motor, which it is an actuator. Once sensors catch the information also the heating and ventilation systems must act.

1.7 Project Planning

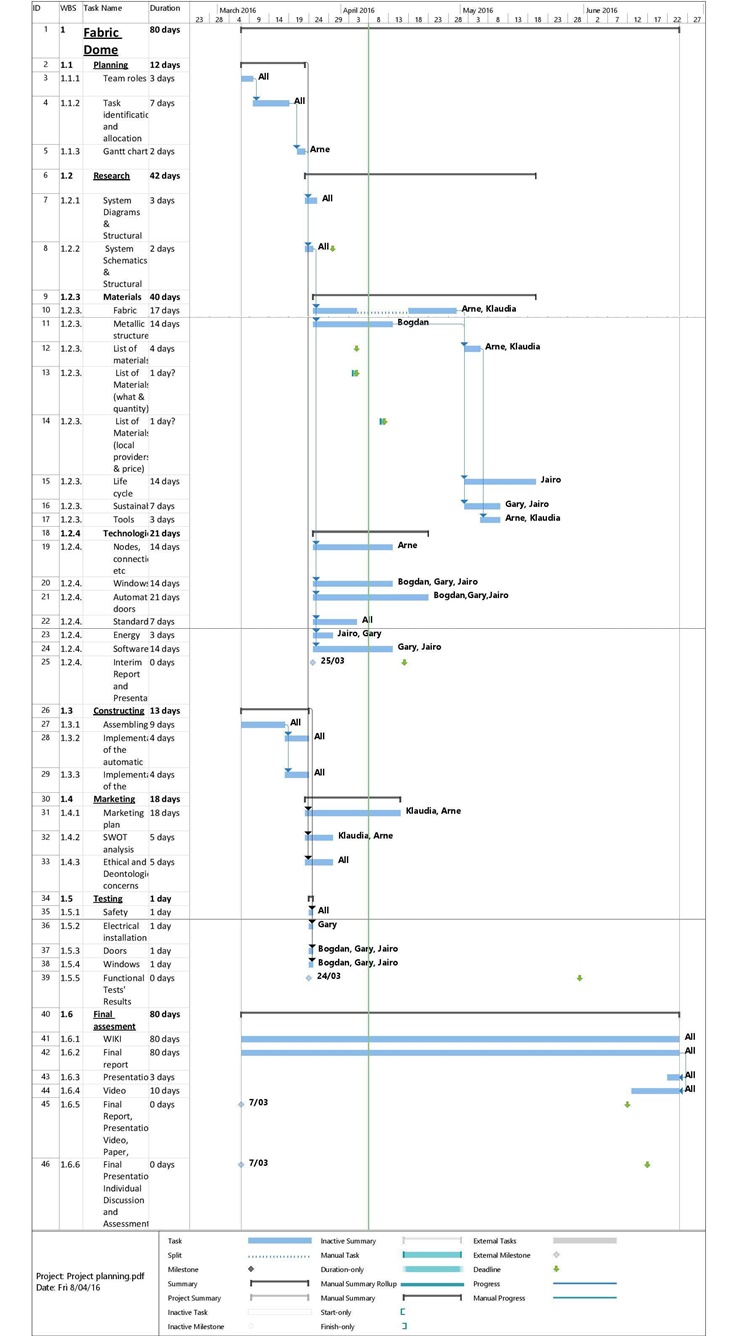

Once we have defined the tasks, we have allocated them according our fields of study and own knowledge. This is shown in the following table.

<WRAP box center centeralign 400px>

| Task | Description |

|---|---|

| Teamroles | All |

| Task identification and allocation | All |

| Ganttchart | Arne |

| List of materials | Klaudia, Arne |

| Fabric | Klaudia, Arne |

| Metallic structure | Bogdan |

| Life cycle | Jairo |

| Sustainability | Jairo, Gergely |

| Tools | Klaudia, Arne |

| Nodes, connections, etc | Arne |

| Windows | Bogdan, Jairo, Gergely |

| Automatic doors | Bogdan, Jairo, Gergely |

| Software | Gergely |

| Standards | All |

| V3 or V4 dome | Arne |

| Logo, brand, etc | Klaudia |

| Sketches | Arne |

| 3D design | Arne |

| Assembling | All |

| Implementation of the automatic door | All |

| Implementation of the windows | All |

| Marketing plan | Klaudia, Arne |

| SWOT analysis | Klaudia, Arne |

| Ethical and deontological concerns | Bogdan |

| Assembling and constructioning | All |

| Windows tests | Bogdan, Jairo, Gergely |

| Doors tests | Bogdan, Jairo, Gergely |

| Safety | All |

| WIKI | All |

| Report | All |

| Presentation | All |

| Video | All |

</WRAP>

1.8 Report Structure

This report is structured in the following chapters. Each chapter contains the information of the tasks before mentioned.

- Introduction. It includes relevant information about our team and a brief summary about our project and what we want to get.

- State of the Art. We will know the level of development achieved until now, from building dome till some kinds of connections or some mechanisms to open doors and windows.

- Project Management. To have success in our project we need to focus on scope, time, quality, cost and people.

- Marketing plan. This chapter will define a solid strategy of marketing. The main objective is to be different of the others competitors.

- Eco-efficiency Measures for Sustainability. Having present the concept of eco-efficiency, we will analyse each one of the three pillars of Sustainability: environmental, social and economical. Also we are going to study the Life Cycle Analysis (LCA).

- Ethical and deontological concerns. This chapter talks about which will be our homework, obligations and ethics that we must take on to make our project.

- Project development. It includes a report about all used components. Moreover we are goin to detail every test and every progress realized.

- Conclusion. Once we finish our tasks, we’ll be able to check if our project has been made successfully.

2. State of the Art

2.1 Introduction

In this chapter we are going to dig deeper in different concepts of building a metallic/fabric dome, which can be used for a winter garden or green house. First of all, we are going to start with a general introduction of designing and constructing a dome. After this, we will talk about some other different topics that are important in order to build a fabric/metallic dome. At the end of this chapter, we will make a conclusion about what the best solution is for our dome concerning heating, ventilation, automatic operation of the doors and windows , etc.

2.2 General concepts of building a dome

A dome is an architectural element consisting a hemisphere (half of a sphere) or the upper half of an ellipsoid. Mostly architects choose to construct a dome which isn’t fully spherical, because it is easier to obtain a more or less spherical dome than to construct a fully spherical dome. The base of a dome can be a circle, ellipse, square or polygon, etc. If you look at the history, a dome was primarily used as a roof for a building. Currently, a dome is increasingly used as a complete structure. In this project we will only focus on the domes which are used as a complete structure. There are different possibilities to construct a dome - see Figure 1. Depending on the usage of the dome, there can be made a decision about the fact what the best option is in order to obtain a structure.

Different applications for a dome are:

- Controlled atmosphere: Green house, Winter garden.

- Shelter

- Storage

- Housing or an extention of a home.

- (Pop up)-events

- Art

<WRAP centeralign>

</WRAP>

The application is also very decisive for the choice of the materials that are to be used. If the dome must be movable, then there should be used materials with a light weight. Dependable on the application for the dome, the material that will be used to cover the dome should also be able stop the effects of wind wind, rain, sun, etc. There are also a lot of other things that should be taking into account when choosing the materials, for instance resistance, elasticity, strength, corrosion, etc.

A big question while designing a dome is how to acquire the spherical structure. There are a lot of well-known ideas in order to get this structure. The most common used technique is to acquire the structure with icosahedrons. A icosahedron is a polyhedron with 20 faces. All lengths and surfaces are equal. This makes the implementation very easy, because all the elements have the same shape. Another possibility for constructing the spherical structure is to use squares and rectangles. The problem here is that all rectangle or square have another shape. This makes it more expensive and difficult to build.

2.3 Problems regarding a metallic/fabric dome

As mentioned in the introduction, our task is to develop a metallic/fabric dome that consists of modular pieces. There will also be an automatic door and -windows implemented in the dome. there are some things that should be taken into account while designing the dome. Below you can find some summed up facts which are important during the design phase of constructing the dome:

- Fabric: The fabric should probably be made in one piece. This essential in order to don’t let water infiltrate in the structure. We can also opt to implement the fabric in the modular pieces. But this makes the construction more expensive, more difficult and less resistant against water infiltration.

- Modular pieces: The modular pieces must be made a very good accuracy. If this isn't done, problems can be caused because the assembly could fail.

- Connection nodes: For a metallic dome the most common used connection is just a simple plate with only one hole for each bar. This makes it possible to change the angle between the bars very easily. A big disadvantage is that the node acts like a hinge. Thus it can’t support bending. But normally this doesn't cause a lot of problems.

- Doors and windows: The doors and windows should be operated very easily. Furthermore, the windows should be implemented in the fabric. This means that the weight of the windows should be very light.

2.4 Advantages and disadvantages of a dome

A dome has a lot of advantages and disadvantages, mostly due to the shape of the construction:

- Energy efficiency: Thanks to the shape of the dome the ventilation and heating system can work more efficient and with less losses. Geodesic domes are able to save up to 50 % on energy costs compared with a structure with the same volume. This will be discussed more elaborately in the chapter ‘Components of a geodesic dome: Heating and -Ventilation”. It is also a good structure to effectively implement alternative energy [2].

- Strong and rough structure: Another advantage is that a dome is a strong and rough structure. Domes are mostly made of triangular pieces, which can spread out the weight of the home and the applied forces more evenly than traditional pieces. Applied forces can be easily distributed over the structure. Domes also have a really high strength-to-weight ratio. This means that a strong structure can be obtained with a small amount of materials. According to an article in Tech Directions in 2007, building a dome can lead to 40 % of savings in materials.

- The aerodynamic shape and the low gravity point of a geodesic dome makes that the structure is extreme capable in resisting strong winds, tornadoes, hurricanes and earthquakes [3].

- Assembly: The time to assemblage a dome is very few compared with other structures with the same size. Since it is a low-weight structure, it is also possible to move the dome easily by a truck or even a helicopter

- Light and sound characteristics: due to the spherical shape of the dome, it distributes sound and light evenly over the whole volume. Outside sound can also be reduced in the dome for approximately 30 %.

Apart from the advantages, there are a few disadvantages that we must take into account [4]:

- Unusable space: Normal homes or buildings have rectangular shapes. Since that most of the furniture, garden boxes, etc. are rectangular as well, it is difficult arrange it in a spherical structure without having unusable space

- Fitting doors and windows: There are a lot of different ways to fit a window or a door in a traditional structure. Since a dome is made out of triangles and not out of rectangles, it is more difficult to find or construct a system for the door or window.

- Waste of materials: In order to cut out the cover for the dome, there will be a percentage between 10- and 20 per cent of fabric that will be wasted. [5]

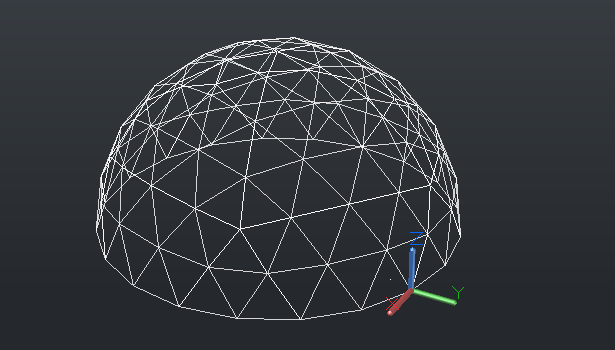

2.5 Mathematics for constructing a geodesic dome

There are a lot of different ways to construct a dome. In this case, we are making a geodesic dome that is derived from an icosahedron. This is a shape that has 20 equal faces, 30 equal edges and 12 vertices. An icosahedron can easily be drawn in a 3D CAD software, by using three equal rectangles that have the same center. The planes of the three rectangles should be perpendicular to each other. Also, the ratio between the length and the width of the rectangle should be the golden ratio φ. Equation 1 shows you the exact value of the golden ratio.

<WRAP centeralign> \begin{equation} φ\ =\frac{1+\sqrt{5}}{2} \label{eq:goldenratio} \end{equation} </WRAP>

If you draw the three rectangles with the different boundary conditions that were described in the previous paragraph, you will obtain a shape as shown in Figure 2. This shape has 12 different vertices from the three rectangles. If we connect all those different vertices with their five other vertices, we will obtain an icosahedron.

<WRAP centeralign>

</WRAP>

The vertices of the icosahedron have the attribute that they can be connected on the same sphere, where the diameter of the circle is the distance between two opposite vertices. The radius of the sphere can be calculated with the equation 2 where s is the length of the edges.

<WRAP centeralign> \begin{equation} r=\frac{\sqrt{10+2*\sqrt{5}}}{4}*s \label{eq:radiusdome} \end{equation} </WRAP>

Due to the fact that the vertices can be connected on the same sphere, it is a good starting point for making a dome. To make a more spherical structure of an icosahedron, we need to divide the different faces into smaller triangles. If the new edges of the smaller triangles are projected on the sphere, it will obtain a better spherical structure. Depending the amount of the divisions, the structure will be more and more spherical. If we talk about domes, we often refer to frequencies as the amount of the divisions that are made on one edge of an icosahedron. Our dome will have a frequency of 4 V. [6] This means that all the edges of the dome will be divided in 4 pieces. Figure 3 shows you the three different steps to make a better spherical structure.

<WRAP centeralign>

</WRAP>

2.6 Components of a geodesic dome

2.6.0.1 Introduction

In this chapter we will describe different components of a geodesic dome and the different possibilities/methods to implement the components into the dome. The components are either important for obtaining a good structure of the dome, e.g., the connections, materials, etc. Other components are important for maintaining a good and liveable climate in the dome, e.g., ventilation, heating. The different possibilities that are described in this chapter isn't a summary of all the different possibilities that can be used. We only tried to make an overview of the different components that can be used in a geodesic dome and particularly a metallic/fabric dome that can be used for a low-cost greenhouse.

2.6.0.2 Heating

There are a lot of different heating systems. Each heating system has their advantages and disadvantages. This causes that not every heating system can be used for every application. For this application we must think about different aspects when we want to choose a heating system. First of all, the heating system must be mobile. Our dome will be easily assembled. If we want to move the dome to another place, the heating system has to be moved very easily as well. Second of all, we must think about economics. the heating has to be a low-cost system. A greenhouse dome isn't a place where you'll be living. This means that there is no need for intensive heating. Furthermore, we must also consider the influence on the environment when we want to choose a heating system.

The spherical structure of the dome brings a lot of advantages concerning heating. As shown in Figure 4 , the dome always has maximum solar gain throughout the seasons. At every time of the day when the sun shines, it can transmit the sunlight at a perfect angle on the dome. This is very interesting during the winter when the sunlight has a big deal in the heating process of a dome. During the summer it can cause overheating. This problem can be solved with a good ventilation system [7].

<WRAP centeralign>

</WRAP>

Another advantage for a dome is that it has a very good air flow. The warmth or cold will be spread evenly across the whole volume. As a result, there will be a uniform temperature inside the dome. The amount of temperature that will transmit in or out of a closed constructed is strongly influenced by the size of the outer surface of the construction. Since a sphere, and thus a dome, is the best shape to have the less surface area per unit of internal volume, it is the best way to reduce the temperature loss or gain. A good example can be found in Greenland and North Canada. Eskimo’s make a spherical constructing because that is the most effective way to shelter for the cold. Also new designs for research bases in polar climates are mostly based on a spherical structure. Due to the different advantages that were pointed out in this chapter concerning the heating of a dome, there won’t be needing an extensive heating system or even no heating system at all. If the consumer chooses to implement a heating system, there are different systems that can be considered to use:

- Wood or pellet stoves: This is an easy and sustainable way to heat a volume. Burning logs will give warmth to the dome. The smoke can be easily removed from the dome by using a chimney. The material that will be used for the chimney should be fire resistant. Another advantage for this system is that the cost price for constructing this heating system isn't high.

- Thermal energy storage: Thermal energy storage isn't an active heating system. This means that it doesn't need energy to heat a volume. It is a system that can store thermal energy so it can be used when the temperature is low. The thermal energy will be stored in a mass. During the summer the thermal mass can heat up so that the thermal energy can be used during the winter. A good material for the thermal mass is water, because it is one of the easiest material to be installed into the dome, it is easily accessible and it can store a lot of thermal energy.

- Solar energy: Another way to generate heat is to use solar energy. For heating, solar energy can be used in 2 different methods. The first method uses solar panels to generate electricity. This electricity can be used to heat up water and to actuate a pump which will distribute the heat in the dome. Another way to use solar energy for heating is with a solar water heating system which uses the radiation of the sun to heat water. This water can be stored in a tank. If the tank is placed just above the solar radiating panels, it will create a natural convection that exchanges heat. Thus, it can be possible to use this system without a pump.

2.6.0.3 Ventilation

A greenhouse and winter garden should contain a ventilation system in order to control the temperature in the dome and to ensure that there will be a good climate in the dome. Due to the spherical shape of a geodesic dome, it is very easy to have a great air flow. The air and temperature will be spread evenly over the whole volume. Figure 5 shows you the main air flow in a dome structure [9].

<WRAP centeralign>

</WRAP>

Hot air will rise up to the top of the dome. A very simple solution to implement a ventilation system will be to install vents on the top of the dome, e.g., a window. The hot air will be able to escape on the top. Thereby, the air pressure inside the dome will be lower than outside. If we want to let the cold air go inside of the dome, it should also contain vents on the bottom of the structure. This causes a chimney effect which makes that the dome can be ventilated really quickly. If this solution is implemented in the dome, there should also be a (automatic) system which can open and close the vents when it is needed. This system has a low energy consumption if we compare it with other possible ventilation systems.

Another solution to ventilate a dome is to use cooling fans. The problem with this solution is that you need a lot of energy in order to power the cooling fans. It is possible to power the cooling fans with solar panels.[11] Since this dome will only use a 12 V battery, it’s almost impossible to use it in this case.

2.6.0.4 Connections

One of the tasks in this project is to find a simple, robust and innovative way to connect the different struts with each other. Currently, there is a variety of connections. If we look at the connections that have already been used on a geodesic dome, we can distinguish two different approaches. One approach is to use well known/standard connections, e.g., a simple plate with one bolt for each bar. These connections are simple and easy. It is also easier to find providers for the connections. We can also approach this problem in a more innovative way. The structure of the connections is more complex than standard connection, resulting in a higher cost. Nonetheless, it can bring a lot of advantages regarding assembling, a better resistance for bending and buckling, etc.

In table 1 you can find different standard and some innovative connections that are already in use or have been patented. In this table you can also find some advantages and disadvantages for each type of connection.

</WRAP>

2.6.0.5 Automatic windows and doors

In order to control temperature and humidity inside dome, we are going to find an innovative system that was be able to open or close windows and doors any time. For instance, if climate gets hot, the system responds by opening doors or windows. Instead if climate gets cold, the system responds by closing doors or windows.

This system should not be too expensive, neither should consume too much energy and, of course, it needs to be easy to install and to maintain. However there are not too much systems like that on market, so its price, obviously, increases. Also it has a sophisticated technology, therefore also its price increased.

We were searching innovative systems to accomplish this automatic task but as we said, market is limited and the prices are so high. Everything that we found was too expensive and it double our initial budget. Also we didn't find a lot of automatic systems applied directly on domes. Therefore, it can give us some advantage above our competitors.

In table 2, you can find some kind of devices with its advantages and its disadvantages, respectively. Some of these devices can be implemented on windows and doors as well.

</WRAP>

2.7 Materials

Concerning the materials there are different options that can be considered. In table 3 you can find the three main materials which can be used for the construction of a metallic geodesic dome. You can also find the main properties of the materials and the price in this table. Since there are a lot of different alloys for each material, we used the alloys that are the most common for each material. <WRAP centeralign>

| Material | Elastic modulus (MPa) | Tensile strength (MPa) | Yield strength (MPa) | Density (kg/m³) | Price (€/kg) | Advantages |

|---|---|---|---|---|---|---|

| Aluminium 6061 [12] | 69 | 65-110 | 110-152 | 2700 | 1,75 | Low-weight, corrosion resistant, recyclable |

| Steel s235 [13] | 210 | 235 | 360-510 | 7850 | 1,31 | Easy to mold, heavy, corrosion has a big influence |

| Stainless steel 420 [14] | 200 | 345 | 655 | 7800 | 1,19 | Corrosion resistant, heavy |

</WRAP>

If we look closely to this table, we can conclude that stainless steel has the best mechanical properties (Elastic modulus, Yield strength and tensile strength). It has also a good resistance against corrosion. In comparison with aluminum, the price per kilogram is also cheaper. Nevertheless, stainless steel is a very big disadvantage that it is very heavy. On the other hand, aluminum is a very light material which has a good resistance against corrosion. The price for aluminum is higher, but since it has small density in comparison with steel and stainless steel, you can obtain a bigger volume of aluminum for the same price in comparison with the other materials. The mechanical properties of aluminum are smaller than those of steel and stainless steel, but they are not that small that it can’t be used as a material for our dome. Furthermore, there is steel. This material has a big advantage that it has a bad resistance against corrosion.

Apart from the materials that we need for making the metallic structure, we also need fabric to cover our dome. For the fabric, we can also distinguish different materials. In table 4 we made a list with different materials for the cover of our dome and their properties.

<WRAP centeralign>

| Material | Properties | R-Factor (K*m<²/W) |

|---|---|---|

| Clear marine vinyl[15] | Flame resistant, Waterproof, Highly resistant to mildew, durable | 0,61 |

| Polyethylene plastic[16] | Inexpensive, not very durable | 0,83 |

| Solexx twin-wall polyethylene cover 3,5mm [17] | Strong, accelerates plant grow, good insulation, good durability | 2,10 |

</WRAP>

2.8 Examples of previous designs

Two main things need to be considered while making a dome. First of all, the cost price should be as low as possible. The second thing that need to be considered is the benefits of the product. Those two aspects are bound to each other. In order to have a lot of benefits, a higher cost price will often result in more benefits and vice versa. In this chapter, two examples are given from previous designs. The dome ‘Garden Igloo 360’ is a low-cost dome from the company ‘Garden Igloo’. The second example is a dome from the company ‘pacific domes’ and has more benefits, resulting in a bigger cost. [18]

2.8.1 Example 1: Pacific domes

This geodesic dome uses Metallic struts to provide the structure. The struts are connected with one simple bold for each connection, which makes it easy to assemble this product. The time to assemble this dome is also fast in comparison with other type of nodes, since you need only one bold for each node. The structure of the dome is derived from an icosahedron. There are two doors implemented in this dome. which occupies a full hexagon. The doors can’t be opened automatically. Instead they have to be opened manually by using a zipper. These doors can also be used to connect two domes with each other[19].

</WRAP>

Figure 1: Green house of the company 'pacific domes'[8] There is also a system for the ventilation implemented in this dome. A piece of the fabric on the base of the dome can be rolled up if necessary. This allows that a great air flow can be infiltrated into this dome. In addition, the roof can be opened, resulting in a chimney effect and in an even better air flow. Another interesting element of the ventilation system is the solar air vent. This is a fan powered by solar energy which can be utilized in a fabric dome. Since it uses solar energy, it can be considered as more or less environmental friendly. A disadvantage of this system is that, without any battery, the vent will only work when there is a sufficient amount of sunlight.

2.8.2 Example 2: Garden Igloo 360

Another example of a geodesic dome is the “Garden Igloo 360” from the company Garden Igloo. This is a low-cost geodesic dome with a diameter of 3,6 meters. It is obvious that this company has designed this dome, so it would result in a lot of advantages regarding the cost price, fast assemblage and sustainability. This dome uses PVC as material for the struts. According to Garden Igloo itself, the time to assemble the dome only takes two hours if it is executed by two persons. Also, this dome uses connectors without screws. This also means that this dome can be built without needing any tools. This dome uses 100% recyclable materials. Except for the screws, everything in this dome is made out of PVC. This includes also the cover of the dome.[21].

</WRAP>

This dome uses nine different struts and there are also six different connectors. Knowing that you can build a geodesic dome which has almost the same structure as this product with only 3 different pieces, we can conclude that there are too much different struts and connections in this design. The dome can also be transformed to a ‘summer canopy’. There will be even three extra different connections needed. There are two air vents implemented in the cover of the dome. They can be easily opened by using a zipper. Opening the air vents will provide ventilation for the whole space.

2.8.3 General findings of other examples

Besides the two examples that are described more elaborately, there are different other examples available. In general, there are some conclusions that can be drawn from our findings. First of all, the most common technique to connect the struts that is used for domes with a comparable diameter as our dome, is to use only one bolt that connects all the different struts on one node. Second of all, the most common used material for the struts is aluminum. This material has a low-weight and has a good resistance against corrosion, which makes it an ideal material that can be used in outside areas. At last, almost every structure of a spherical dome that has come across during this research is derived from the structure of an icosahedron.

If we look closely to this table, we can conclude that stainless steel has the best mechanical properties (Elastic modulus, Yield strength and tensile strength). It has also a good resistance against corrosion. In comparison with aluminum, the price per kilogram is also cheaper. Nevertheless, stainless steel is a very big disadvantage that it is very heavy. On the other hand, aluminum is a very light material which has a good resistance against corrosion. The price for aluminum is higher, but since it has small density in comparison with steel and stainless steel, you can obtain a bigger volume of aluminum for the same price in comparison with the other materials. The mechanical properties of aluminum are smaller than those of steel and stainless steel, but they are not that small that it can’t be used as a material for our dome. Furthermore, there is steel. This material has a big advantage that it has a bad resistance against corrosion.

2.9 Conclusion

A dome is a very interesting structure due to the many advantages that it has regarding the strength, the usage of materials, the low weight and the fast assemblage. Nevertheless, there are still some problems where a good solution still has not been found. Nowadays, there are different techniques available on the market for each component of a dome. Nevertheless, most of the domes that are already design and constructed, use almost the same techniques. This phenomenon can have two explanations. First off all, the techniques that are used most of the times are the most available and easiest technique in the market. Another explanation can be that this technique is just the best technique that can be used for this application.

3. Project Management

3.1 Scope

Project scope is a fundamental part of project planning, it determines list of our project goals and tasks-things that need to be accomplished to deliver a product. Our scope is to design and build a portable, yet durable, metallic&fabric dome, which will be used as winter garden by potential customers. What is more, it should have useful capabilities, for example automatic door and windows-which should open if the temperature or humidity in dome will be too high or too low from those the previously set by the customer. Taking all of our expectations into consideration, our dome has to be:

- Sustainable – to provide long-lasting obsolescence

- Appealing to customer - as a leisure time place, this is one of the most important aspects

- Low-budget production – when it comes to price, we want to spend as little as possible in order to earn, but this may not be at the expense of quality

- Portable - customers should be able to assemble the dome by themselves

Also we are obligated to prepare deliverables:

- Interim Report

- Interim Presentation

- Leaflet

- List of Materials & Components

- Final Report

- Final Presentation

- Paper

- Poster

- Manual

- Video

In order to organize our work properly our group made a Work Breakdown Structure (WBS) which is presented in Figure 8.

<WRAP centeralign>

</WRAP>

3.2 Time

All of the plans and tasks need to be arranged in time, so we decided to do a Gantt Chart that would show our planned deadlines as well as task allocation. That kind of tool allows us to control our work and make sure that everything what needs to be done is being fulfilled in time.

We used Project Libre to execute the Chart. It illustrates tasks and stages of our work from the beginning of the project (07.03.2016) till the end (22.06.2016) of the semester.

The chart is presented below in Figure 9.

<WRAP centeralign>

</WRAP>

3.3 Cost

Our budget for the project, to build the model, is 100 € and it’s due to us to manage the costs that way so we could fit into it. We can divide our costs in direct and indirect: Indirect- ones, which are covered by ISEP-so using the space, laboratories, work of teachers and supervisors and also our work, as for now we are not making any money, even if we include us in planning (Gantt chart), these costs are presented in Figure 10

<WRAP centeralign>

</WRAP>

Direct-ones, which are connected to building the scale model-so materials and fabric, these costs are presented in Figure 11

<WRAP centeralign>

</WRAP>

3.4 Quality

In order to deliver a high quality product-in our case a prototype (scale model of the dome), we have to determine all of the steps that need to be taken to complete the task. Certainly, we can distinguish some of the aspects, like:

- EPS standards

Which are monitored by supervisors and teachers. Meetings with supervisors are taking place every week so our progress is being verified. What is more all of our questions and insecurities are being answered, so we are able to move forward with completing the project.

- Satisfaction of every team member, customer or investor

First, we need to understand and define expectations of the customers to meet their needs, because their opinion about our project is the most important one. If expectations are not fulfilled, the product is not seen as a good quality one. The other aspect is satisfaction of team members, as all of them need to be fully involved in designing a product, as the quality of it depends on them.

- Technical quality of the product

The most important aspect of the technical quality of the product is its safety. The structure needs to be designed and built in proper way, to make no harm to potential clients, users but also us-authors of it, as we are the ones who are going to run tests on it.

3.5 People

When it comes to people within project, all of individuals who are somehow involved in process of realization the task need to be taken into consideration. One of the aspects that need to be analysed is approach to work, behaviour during the process. We have to monitor involvement in work, how people cope with assigned tasks, if they are doing fine or if they need any help, because it can be too much for them-because they are overwhelmed by the pressure of other team members or time, or they are just unwilling to finish the task.

We started our work by dividing tasks among team members, so everyone could use their individual strengths in specific parts of the project-table 5.

<WRAP centeralign>

</WRAP>

After segregation of the tasks, we were able to do the Role and Responsibility Matrix, also known by other name RACI matrix-table 6, which helps to illustrate roles and responsibilities of people related to the project. The name is an acronym which stands for four roles in realization of tasks:

- Responsible-person who is responsible for the execution of the task

- Accountable-person who is responsible for correctness of the projects, often delegates work to responsible

- Consulted-person who reviews the outcome of the activity

- Informed-person who is informed about results of the activity

<WRAP centeralign>

</WRAP>

3.6 Communications

Communication is a key element which has to be applied effectively for a project’s life cycle from the beginning till the end. As team members we have to talk to each other and discuss all of the steps during the process of creating a product to work together in a best possible way. We can distinguish various methods of communication among team members of our team:

- Face to face communication

We mainly communicate with each other orally. We meet almost every week day on University during classes, where in between lessons we discuss some smaller ideas and also we have meetings once or twice in a week to brainstorm, discuss problems, doubts, progress and goals. After this kind of meetings we divide some new tasks among everyone, so they can be done at home. But team members are not the only one during the process of communication. We also have meetings with supervisors once a week, when our steps are analysed and we get some feedback regarding our work.

- By Internet

In our time we can stay in contact with everyone continuously. We created a Facebook group, where we share every files related to our project-sketches, schemes, some parts of wiki reports and because of that we can comment and give some feedback and advices without having to leave our homes. We also can talk to each other in case of doubts and we don’t have to wait for next group meeting. In this place we arrange appointments. We also use e-mails to communicate with our supervisors in case

Table 7 presents communication processes among all people related to the project.

<WRAP centeralign>

| What | Who | How | When | Why | To whom | Codification Comments |

|---|---|---|---|---|---|---|

| Weekly Supervisors Meeting | Team | Meeting-Face to face | Every week | To discuss work that has been done and get feedback | Supervisors | Agenda |

| Group Meetings | Team | Meeting-Face to face/Facebook- Messages | Once or twice a week/Every day | Exchange ideas | Team | Notes |

| Interim Presentation | Team | Meeting-Face to face/Presentation | Once, 21-04-2016 | Midterm feedback | Supervisors | Presentation, notes |

| Final Report | Team | Wiki | Once, 11-06-2016 | Compulsory delivery | Supervisors | Report |

| University Classes | Teachers | Classes-Face to face | Every day | Provide knowledge that is needed during the project | EPS Students | Presentations, notes |

</WRAP>

</WRAP>

3.7 Risk

Every undertaking is connected with possible risk at some point of the realization. Being aware of this fact, it helps to identify risks that jeopardise during the process of creating the project. What is more by decreasing threats we can develop opportunities that occur.

Because of that we decided to identify and analyse all of the potential risks and after this think of possible solutions to every problem. It's illustrated in Table 8

<WRAP centeralign>

| Risk | Cause | Consequence | Risk Response | Trigger | Owner | Last Review | Frequency |

|---|---|---|---|---|---|---|---|

| Model won't work properly | Bad designing, constructing | All parts that are connected will have to be checked and maybe changed | We have to make sure that everything is properly designed and will work together (Mitigate) | Functional tests | Gary | 23-05-2016 | Once |

| Badly selected materials | Unclear information from providers, non-thorough research | We won't be able to build the scale model, there will be time delay | Materials have to be discussed with supervisors, we also need to check them before starting the construction (Avoid) | Quality checks | Arne | 11-04-2016 | Once |

| Broken parts | Quality; Bad treatment | We will have to order new ones, there will be more money spent and time delay | All of the parts need to be handle with care, there needs to be quality check (Mitigate) | Quality checks | Bogdan | 03-05-2016 | Every week |

| Poorly functioning team | Lack of communication | Lack of communication, no keeping the deadlines | All of the problems, assignments need to be discussed (Mitigate) | Team meetings | Klaudia | 22-02-2016 | Every week |

| Health problems of one of team members | Illness | Everyone will have more work, possible delays | Adapt to new situation, some work can be done from home (Accept) | Communication | Klaudia | 22-02-2016 | Every day |

| Not meeting the deadlines | Bad planning | Lower grades | Try to prevent this kind of situation (work with the time schedule, if not - explain the situation to supervisors)(Accept) | Checking the deadlines | Klaudia | 29-02-2016 | Every deadline |

| Materials not coming on time | Provider; Bad planning | Time delay, we are not able to do the project | Make material list on time, before the deadline, so ISEP has a lot of time to buy them (Transfer) | Checking the deadlines | Jairo | 11-04-2016 | Once |

</WRAP>

</WRAP>

3.8 Procurement

Procurement is known as act of acquiring and buying supplies needed by company from external suppliers (sources). Procurement management allows to save money, but in the same time it doesn't affect quality, as this is one of the most important factors when it comes to the product. To choose our suppliers we were obligated to target only that ones in Portugal, so we had limited options, especially when it comes to price, because it would be cheaper to buy from suppliers from other continents. But it also has positive aspect, as we cannot afford any delays in designing and building our prototype, so having a supplier in the same country or even city ensure a quick realization time of the order. Summarizing, we choose local (Portuguese) distributors and we focus on price, but it also needs to come with as best quality as possible.

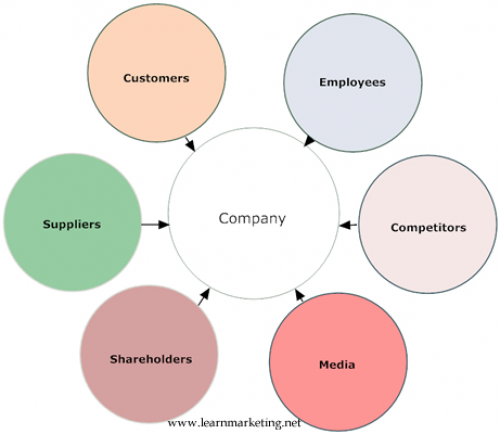

3.9 Stakeholders management

Stakeholders management allows to identify people who are involved in the project and have a certain power and interest, it means that stakeholders are individuals or group of people who can affect or be affected by project. When it comes to our project we can outline different types of stakeholders, like:

- Firstly, the group which is mostly connected to the project-our team. The outcome of every part of the project depends on us and the quality of our work.

- The second stakeholder are supervisors who are sharing their views and opinions about our project and progress. It means they have a big influence on our work.

- Next group are teachers (Marketing, Project Management, Communication, Ethics and Sustainability) who are delivering knowledge to us which will help us during the process of creating project.

- We also identify as stakeholders our team supervisors Abel Duarte and Fernando Ferreira who are following our work and giving us specific advices.

- And the last one is Benedita Malheiro. We see her as a stakeholder because she manages the whole EPS program and as a head of supervisors her opinion is very powerful.

Table 9 presents each stakeholder's level of power and interest

<WRAP centeralign>

| . | Name of Stakeholder | Role | Expectation | Power | Interest |

|---|---|---|---|---|---|

| 1 | Project Team | Authors of the project | Creating a good working project | High | High |

| 2 | Supervisors | Oversee the project | Quality of work is satisfying | Medium | Medium |

| 3 | Teachers | Giving knowledge | Correctly implement the giving information in the WIKI | Low | High |

| 4 | Team supervisors | Overlook the project | Quality of work is satisfying | High | High |

| 5 | Benedita Malheiro | Chief Supervisor | Deliver a complete project | High | High |

| 6 | ISEP | Provide space and money for the project | Deliver a project | High | Low |

| 7 | Family of team members | Giving support | Team members to be satisfied with exchange program | Low | Medium |

| 8 | Hometown Universities | Giving the opportunity of EPS program | Pass the program | Medium | Medium |

</WRAP>

</WRAP>

Figure 12 presents the Stakeholder matrix.

<WRAP centeralign>

</WRAP>

3.10 Conclusion

In this chapter we presented aspects of project management connected to our task. As planning and organizing are crucial during the process of developing a product we had described every element which is a part of project management, like time, people, quality or risk. We started with division our work to smaller tasks and then we assigned them to different people, so every team member can use his strengths to help project to evolve, we also described approach each team member to every task. All of them also have deadlines, which we presented on Gantt chart. What is more, we described the problem of costs of the project, as we have a limit of 100 €, so we needed to fit into this budget, which we did with the total cost of 96.14 €, taking into consideration quality of the product, our service and also suppliers of parts. We described risks that may be encounter during the process of designing and building our product. And we also focused on the most important aspect-people. We analysed communication between everyone who is involved in the project, starting with us, authors of product, supervisors and teachers. Stakeholders have been studied, so we described what kind of power people involved in our project have over it.

In the next chapter we are going to focus on different important aspect of every product or service-marketing.

4. Marketing Plan

4.1 Introduction

“Marketing is getting the right goods and services to the right people at the right places at the right time at the right price with the right communications and promotion.”

In this chapter we are focusing on the market of our product, as this is one of the most important things, to learn to whom we are dedicating our service. With every part of this chapter we are going to explain and expand on market, threats and opportunities or budget. After this kind of elaboration we will be able to understand better our clients, competitors, goals as well as a product itself.

4.2 Market Analysis

4.2.1 Macro environment

A Macro-analysis is an analysis that focusses on some different factors that can influence the market. One main aspect that the different factors all have in common in a Macro Environment analysis is that the companies are unable to control those factors. A PESTLE analysis is a useful tool to do a Macro analysis. This is a concept in the marketing environment that refers to the 5 main groups where we should base our Macro-analysis on: Political, Economic, Social, Technological and environmental [23].

</WRAP>

4.2.1.1 Environmental/Social:

Nowadays more and more people are aware about the environmental issues that the earth is facing right now. According to an article from DESA, the Department of Economic and Social Affairs from the United States, the population have been tripled in the last 50 years of time. In another 50 years, the population will be tripled again. This will make that in the present and the future, more and more people will be longing for an own place, where they can be by their self. Also more and more people will think more about the environment and green aspects. Our product can both offer an own space and a place where they can be in a green environment. This means that, concerning the social environment, our company only has advantages [25].

In Europe, there are more and more people who want to buy organic food. The only problem about this trend is that organic food is far more expensive in supermarkets than normal food. A greenhouse dome would make it possible for the people to grow their own organic food.

A market is heavily influenced by their geographical region, climate conditions, weather, etc. In our example the market is located primarily in Portugal. Being as it may, Portugal has a climate where the weather can vary very easily and where the temperature doesn't drop very low during the winter. This is a positive factor for our product, because our product will be accessible for every time of the year. Our product is also able to give shelter against rain and wind.

4.2.1.2 Technological:

Technology is a factor that on this day changes every minute. We need to try to integrate new innovative technologies into our product. In our product, we will implement different technologies. Sensors will measure the humidity and temperature. Afterwards we will be able to automatically control the heating/cooling and the ventilation of the dome. We will also have a door that can be automatically opened. Our product is also able to be equipped with some innovative and low-cost heating systems.

4.2.1.3 Economic:

An economic crisis is happening in Portugal. Portugal has a lot of debts, most of it being owned abroad. It also seems that there isn't going to be a solution for the crisis in the near future. According to the opinion of financial journalist Matthew Lynn, Portugal is the next Eurozone crisis. This isn't good for our company, because the people will have less power to buy things. On the other hand, it also means that even the richer people will find cheaper solutions to have a luxury product. Since our company will give the consumer a place for themselves and it is still a low-cost product, more clients will consider to buy our product if they are interested in buying a place. Our product is also low-cost in maintenance and can be very efficiently cooled or heated [26].

4.2.1.4 Political:

As for most of the countries is Europe, you will first need a planning permission to construct a space. If you don’t do that and it was necessary, there can be a fine. Since our product has already a reasonable amount of volume, it could be possible that you will need a permission in order to build the dome in your garden. If this is necessary at all, it can scare some clients of who want to buy our product.

4.2.2 Micro-environment

With the micro-environment, we analyse the factors that immediately affect our company in the meaning that it can affect its performance, decision-making and the possibility to serve their clients. The different aspects that should be discussed in this chapter are: Customers, Employees, Competitors, Shareholders and suppliers.

</WRAP>

4.2.2.1 Costumers:

The first aspect is already one of most important aspects in the micro-environment. The costumers are the people who buy our product. In order to have the possibility to keep our business alive, we must establish long lasting relationships with our customers. Momently, approximately 42.2 % of the people in Portugal are between 25 and 54 years old. This is a great amount which Is good, because these are the age group who has the highest possibility to buy our product. In 2011, 61.1 % of the whole population live in an urban environment. Most of the people who live in the city don’t have a big garden, nor a lot of space. Since our product needs a lot of space, our goal will be to target the 38.9 % of the people who don’t live in a city, because they will probably have bigger gardens and enough space to place our product [28].

4.2.2.2 Employees:

Momently, we are a company with only five multidisciplinary employees. One thing that we have an other companies don’t have, is that our employees have been working in this company since the start. Thus, they know every technical- or economical detail, design, material, etc. from our product. This makes that our company has a lot of confidence that our employees will do the right thing to do in any specific situation. Our company really wants to set this mentality as a baseline if we want to employ some future employees.

4.2.2.3 Competitors:

It is also important to analyse the competitors of your market. They will decide how much concurrence there is on the market. If there are too much good competitors in your target market, it would be very hard to obtain a big share in the market and to have a high profit at the same time.

Table 10 presents some of the most important competitors

<WRAP centeralign>

| Company | Description | |

|---|---|---|

| 1 | GardenIgloo [29] | Worldwide provider, based in German, similar products |

| 2 | Cupula Geodesica SL [30] | Worldwide provider, mainly based in Valencia (Spain), provides lifetime warranty |

| 3 | Geometrica [31] | Worldwide provider, mainly based in America, bigger dome projects |

| 4 | Pacific Domes [32] | Worldwide provider, different products, similar products |

</WRAP>

</WRAP>

Another big competitor that is not mentioned in the table, isn't a company. Because of the easy structure of a dome, there are a lot of people who make dome by their selves. You can find several Do-It-Yourself manuals on the Internet so the competitors (the people) can get instructions for the beginning the end, without having to buy our product.

4.2.2.4 Suppliers:

First of all, we should establish a good relationship with the different suppliers. If there isn't trust between the company and the supplier, it can have bad consequences. The supplier should always be able to deliver their components when they need to be delivered and with the quality that was asked for. On the other hand, our company must be able to pay the suppliers on time.

4.3 SWOT Analysis

A SWOT-analysis is an abbreviation of Strength, Weaknesses, Opportunities and threats. It is a tool for analysing the internal strengths and weaknesses, and the external opportunities and threats of a company. By doing the SWOT-analysis for you company, you get a better vision of what your different aspects are in a company who are helpful, so you can use those aspects to obtain a better share in a market. It also helps the company to give them a better vision of what the aspects are who are harmful for the company, so you can eliminate those aspects. Figure 15 shows you our SWOT-analysis.

<WRAP centeralign>

</WRAP>

4.4 Strategic Objectives

The strategic objectives of a company should be well thought-out and easy at the same time. In general, Strategic objectives should satisfy five different requirements, often referred as the SMART principle:

- Specific: Detail exactly what needs to be done

- Measurable: Achievement or progress can be measured

- Achievable: Objective is accepted by those responsible for achieving it

- Realistic: Objective is possible to attain

- Timed: Time period for achieving is clearly stated

In order to do the strategic objectives, we must take some aspects into account which can be deciding to make the strategic objectives happen, like for instance the competitors, the past, the current and future market state, etc. In our company, we agreed to have following objectives:

- July 2016 - Finish our project design

- End of 2016 – Find funding for developing our product.

- February 2017 – Start selling our product.

- End of 2017 – Obtain a decent share in the target market in Portugal (+- 10 %).

- 2019 – Become the market leader in Portugal.

- 2020 – Expand our target market to the countries close to Portugal (Spain, France, Italy).

- 2022 - Obtain a decent share (+-10%) in the market in the countries close to Portugal.

- 2025 - Make our product available worldwide.

4.5 Segmentation

In order to reach the people who want to buy our product, thus reaching the needs of the consumer, it is strongly advised for a company to divide the market into smaller segments. The different segments will all have a different need or approach. The company can use this information to know what the most efficient way is to reach and to fulfil the needs of every different segment. For an effective segmentation, we must fulfil five different requirements:

- Measurable: We are able to measure the size and the purchasing power of the segments.

- Accessible: We are able to reach and to serve the segments

- Substantial: the segments which we would be able to sell our product to, are large or profitable enough to serve.

- Differential: Each segment is different and thus will also respond differently.

- Actionable: We are able to make effective programs to attract and serve the segments.

In the following paragraph we will start our segmentation. In total, we will have four different segmentation criteria:

- Geographic segmentation

- Demographic segmentation

- Psychographic segmentation

- Behavioural segmentation

4.5.1 Geographic segmentation:

Our main target group will be located in Portugal, especially the people who live in a more rural environment in Porto. Those people will mostly have enough place to place a geodesic dome and they are closer to the nature in comparison with the people who have a more urban lifestyle. Approximately 39 % of people the people in Portugal live in a rural environment. There will be some people who live in an urban environment and have plenty of space to install our product, but those people are difficult to reach.

4.5.2 Demographic segmentation

For our product we will target the people in Portugal who are between 25 and 65 years old. In Portugal, approximately 54.1 % of all the people are between 25 and 65 years old. We will both target people who have or who doesn't have children. The income of the people is also an important variable that we should take into account. Our target will be the people who have an income above average. They will the first people who will be able to buy our product.

4.5.3 Psychographic segmentation

Our company should target people who have some typical or different psychological attributes. Our company should focus on the people who:

- … care about the environment.

- … like to be in their garden every time of the year.

- … Like construction and innovative techniques.

- … have the need to buy luxury products.

- … Likes to have his and/or her own space.

4.5.4 Behavioral segmentation

In our opinion, we think that targeting occasional buyers is useless for our type of product. Buying our product will also with some kind of consideration. If we want to target a type a user status, we should target potential- or first-time users. It would be difficult to target regular users, because mostly if you have our product, you don’t need another one. The usage rate of our product by the people that we want to target, should be medium or high. Our product will consist of plants that will need maintenance. This means that the consumer will need to use our product a lot in order to keep the plants how they are supposed to be kept, resulting in a medium or high usage rate.

4.6 Strategy/Positioning

Positioning is an answer to a question who do we want to sell our product to, it’s also a heart of advertising, what is more it gives character to the company. Positioning allows finding a proper place for the product on the market and eliminates the threat of being in the wrong place in the right time. The idea of positioning is getting more and more important as the market is being flooded with products from different companies, so the client has many almost identical things to choose between. To choose ours one needs to see something greater in our brand without even noticing that. Positioning is connected to segmentation. Needs of our segment should be examined properly to know what kind of expectations our customers have and also what our competitors have to offer.

When it comes to the company there are some strategic options of positioning:

- Aiming for strengthen company’s position on the market-in case when the company is the leader

- Increasing or decreasing differentiation of the offer. In this case companies use manipulation of price, intensive promotion or increasement of an offer for some additional service

- Imitative action, when positioning is about similarities to product of the competitor, but to make ones product more attractive one have to find some competitive advantage (e.g., price)

- Presenting a completely new product or service. If it’s not possible to make a product similar to the best ones (imitating only best advantages), one must make it different.

Considering all of the strategic options it’s obvious that for our product and company we should use the third one, as there are similar products on the market, but we need to think about what kind of uniqueness we can offer. We can divide it into 3 steps:

- Identifying possible competitive advantage(s)

- Choosing the right competitive advantage(s)

- Delivering the chosen position(s) in the best way possible.

Taking all of the information into the consideration, we figured out that the market of our type of products isn't big (competitors are described in 4.2-Market Analysis), there are similar products, but most of them are expensive or unappealing. So this is going to be our competitive advantage-lower price and the design. What is more we will differentiate from our competitors by implementing some features that are not available in other products-there are going to be automatic windows, door and control of temperature and humidity inside the dome. We also want to provide the best quality service for clients and potential market-using the sustainable materials. We are going to implement similar tactic as IKEA, provide more features for less money. To achieve all of our goals we are going to monitor and adjust our strategy all the time.

4.7 Adapted Marketing-Mix

<WRAP centeralign>

</WRAP>

Product

<WRAP centeralign>

</WRAP>

Our product is a metallic and fabric dome which is supposed to be used as a leisure time place-winter garden. It has automatic doors and windows which are equipped in sensors monitoring the temperature and humidity inside the dome, so if needed they will open or close-customer is able to set chosen preferred temperature and humidity. What is more our product is durable and portable, so the potential customer can construct his own dome. It is dedicated to people in age of 25-65, but especially those living in houses, as to have a dome they need a space to have it. Our product is a customer friendly one, using the concept do it yourself it encourage people to buy it just to have a satisfaction from building something with own hands. There are already established in the market, however most of them are permanent or much bigger, so they can’t be used by ordinary being for personal use. And even if there are portable ones they don’t have features occurring in our project.

Price

Deciding on price of our product we need to check prices on existing market, compare them and decide what kind of strategy we are going to choose.

- Setting a high price in short time. It’s usually used while products are new or mostly looked for versions among this ones on the market

- Setting a high price, so the product is seen as a prestigious, high quality one. The expensiveness is the reason why people want to buy the product

- Setting a low price to gain market share. It’s only possible when coefficient of price elasticity of demand is high enough, so the lower price induces increasement of sales volume

- Setting a low price to prevent entering the market other products(competitors)

- Setting a low price, but that low that the company are not able to justify them with production, so it eliminates competitors on the market

First of all, we want to set up a price level that will reach our target group. We want to have smaller prices from our competitors to gain market share, and since our product has more to offer (automation, eco friendliness) we are sure we will win people attention. When it comes to price we need to remember about costs that are included in it: materials, production, people, promotion, delivery and of course our company wants to earn on it. At this point is too soon to provide a fixed price, as we are not producing our product yet and we don’t have a budget to start paying for all of the aspects connected to production. We can suppose that the price will be between 350 € and 450 €.

Promotion

The main concerns of promotion are how to reach the target group and which instrument of communication should we use. Nowadays we have many possibilities when it comes to advertisement, starting with traditional:

- print promotion-like leaflets, posters, magazines,

- audio-like radio,

- audiovisual-in television, cinema

or some modern advertisement:

- mobile, on-line, direct marketing, sponsoring, trade shows or public relations .

We need to decide what kind of promotion is the best for our company and product. We are definitely going to choose on-line advertisement, as this is one of the cheapest and also the one that can get widest field of audience. We will create a website for our company, Facebook page and we are going to put advertise on Google. Another option for us are trade shows which specialize in presenting garden tools, furniture, so we can demonstrate our product there and gain some clients by direct contact with them, as most of the people visiting this kind of trade shows are interested in specific products and are our target group. We are not going to resign from traditional form of advertisement, so we are going to use also printed ones-like flyers, posters or magazines, as lot of people after 50 years old are not familiar with usage of Internet and we also see potential clients in them.

Place

The last aspect of Marketing Mix is place, what means a distribution of our product to the clients. Distribution is about making sure the product is available for customers and managing geographical distances. The way we plan our distribution can be crucial, so we need to examine our options and then choose one. We have two main options: selling directly or indirectly to our customers. Selling indirectly means using some other-external distributors, so other company sells our product, direct means that the company doesn't use other resources to sell the product. Both have advantages and disadvantages. When it comes to selling directly to the customer, company has a freedom of actions that it want to take and of course they stay in direct contact with the client, so it’s building a relationship between company and customer. But it’s hard for the company, especially a new one, where nobody had an experience in selling to design a properly working sales department and distribution. On the other hand, selling indirectly allows company to focus on different aspects then distribution, as some other company is dealing with it. But here company itself is not able to control the distribution so it’s dependent on decision making and policy of other and also there isn't any direct communication with clients, which is important during building a recognizable brand. As our company want to build strong relationship with customers we are going to use direct selling, to make our company recognizable and encourage customers to buy from us. First we are going to use Internet and after 3 years we are going to sell our products in specialized trade shows.

4.8 Budget

Taking into consideration our approaches when it comes to promotion, we have to take into account that we will bear the costs. Having that in mind we need to be careful with how much money we are going to spend on every type of advertisement and some other additional costs, since our budget for the first year is around 5000 € - see Table 11.

<WRAP centeralign>

| Printed | Price (€) |

|---|---|

| Leaflet | 250 |

| Posters | 150 |

| Magazines | 200 |

| On-line Media | |

| Website | 2700 |

| 200 | |

| 200 | |

| Others | |

| Trade fairs | 400 |

| Transportation, accommodation | 600 |

| Total | 4700 |

</WRAP>

</WRAP>

We don't plan to spend all of the money, in case we need some in emergency situation.

4.9 Strategy Control

Strategy control is comparing effects of some actions in implementation strategy with planned ones. Main function is to decide if set goals will be reached or point out as early as possible these ones that won’t be accomplished by any reason, so it will be possible to modify them according to changes in the surroundings. To do so, we have to control, plan, gain and process information in the same time.

Essence of strategy control can be presented as:

- Permanent monitoring of external and internal actions and progress in accomplishing strategic goals also realization of strategy of company

- Strategy control includes company, strategic units, main functions of company and operations that are taking place in company

- It is focused on the evaluation of the course and outcome of actions, but also detection and interpretation of signals connected to upcoming changes (upcoming problems) before they induce negative effects on the company

- Strategy control is closely connected to strategic planning- it is an important instrument in implementation and realization of strategy

To measure our performance there are some possible solutions which should be taken at every point of creating and implementing the strategy. We can use checklists, Benchmarking and performance accounting. We also should monitor the level of completing the strategic objectives, in this case we can also use performance accounting or early detection systems. What is more we should monitor not only what is going on inside our company but also the environment, whole market or even political situation. And of course how profitable our promotion is, relationships with customers or the quality of our service.

4.10 Conclusion

Marketing plan needs to be establish in order to analyse competitors, market and needs of customers. First we started with micro and macro analysis and also SWOT analysis. We also described our objectives for the next 9 years, such as finding a funding for a project or gaining market share first in Portugal, then Spain, Italy, France. What is more, market plan allowed to precise our target group and finally marketing mix, so product, price, ways of promotion and distribution. Summing up, our product is targeted to people between 25 and 65 years, caring about environment. What makes it different then products of competitors is appealing design, relatively low price and special features like automatic windows and door. In the next chapter the topic of sustainability is going to be discussed.

5. Eco-eficiency Measures for Sustainability

5.1 Introduction

Since ever many kinds of materials have been used in construction sector as wood, ceramics, straw and so on. These materials don’t produce any environmental impact and its costs are much reduced. In a world where resources are increasingly scarce, we must find tools to analyse engineering designs and try to reduce humankind’s pollution burden. Life cycle analysis, or LCA, help us to quantify the construction effect on environment and try to answer some main topics like greenhouse gas emissions. This tool, specially, try to inform people and take awareness about what is going on. There are many people who worry about environment but there are so few people who really try to solve.

5.2 Environmental

Buildings are an important field for energy efficiency improvements around the world because of their role as a major energy consumer. The measures that keep buildings comfortable, lighting, heating, cooling and ventilation, all consume energy. Using the same amount of material, our dome's round shape can encompass more space than traditional structures. Compared with a similar sized rectangularly-shaped building, the dome will have 30 % less surface area. This can lead to save huge amount of material. The dome greenhouse will actually use about 1 /3 less material to build than a similar sized box structure.[33] These, in turn, leads to a savings of natural resources, energy, and labour. Thus, construction of a geodesic dome involves a minimal disturbance of the environment.

5.3 Economical

- Energy efficiency: Because of their shape and ability to evenly distribute environmentally controlled air, geodesic domes can save up to 30 % - 40 % on energy costs when using traditional power sources. Domes can also Interface very effectively and efficiently with alternative energy sources.

- Electrical power gaining: With the simple addition of a low voltage wiring system, electricity can be supplied with wind, solar, or hydroelectric power. In our point of view, the mobility of the dome is really important. In that case solar energy source seems the best solution. Furthermore solar energy is a clean and renewable energy source. Once a solar panel is installed, solar energy can be produced free of charge and this kind of energy causes no pollution. Solar cells make absolutely no noise at all. Very little maintenance is needed to keep solar cells running. There are no moving parts in a solar cell which makes it impossible to really damage them. Solar power is used to charge batteries so that solar powered devices can be used at night. Unfortunately in some years we have to change the battery which is a kind of a pollution. [34]

- Financing: Solar panels can be expensive to install resulting in a time-lag of many years for savings on energy bills to match initial investments but in the long term, there can be a high return on investment due to the amount of free energy a solar panel can produce.

5.4 Social

- Lifestyle: With global warming influencing consumer-purchasing habits and renewable energy becoming more accessible, people are seeking ways on how to go green and be eco-friendly. Our domes fit to these concepts, we aspire to build environmentally friendly green houses.

- Safety and Eco-friendly feeling: Since their discovery, geodesic domes have been one of the safest havens in areas with the most extreme and violent climates on the planet, since exposure to cold in winter and heat in summer is reduced. Even though the dome uses less material, it’s about five times stronger than a rectangular-shaped building. Additionally, a third less surface area means that a third less heat is transferred to and from its surroundings, saving the average dome home owner about 30 % or more on their average heating and cooling bill.

5.5 Life Cycle Analysis

5.5.1 Introduction and objectives

The study objective will be to determine each life cycle phases that are more meaningful in terms of environmental pollution. These phases will be the following, and then it will be analysed each one of them.

- Materials acquisition.

- Materials processing.

- Manufacturing.

- Packaging.

- Transportation.

- Use.

- Reuse, recycle and disposal.

5.5.2 Materials acquisition

First of all, there are two differentiated groups: construction materials and electrical components. There are so many materials in each group that it would be another project. Therefore we will analyse some of them, the most meaningful materials. They are the following where aluminium and plastic belong to construction materials group.